Introduction

We Offer Specific Solutions

For Each Client

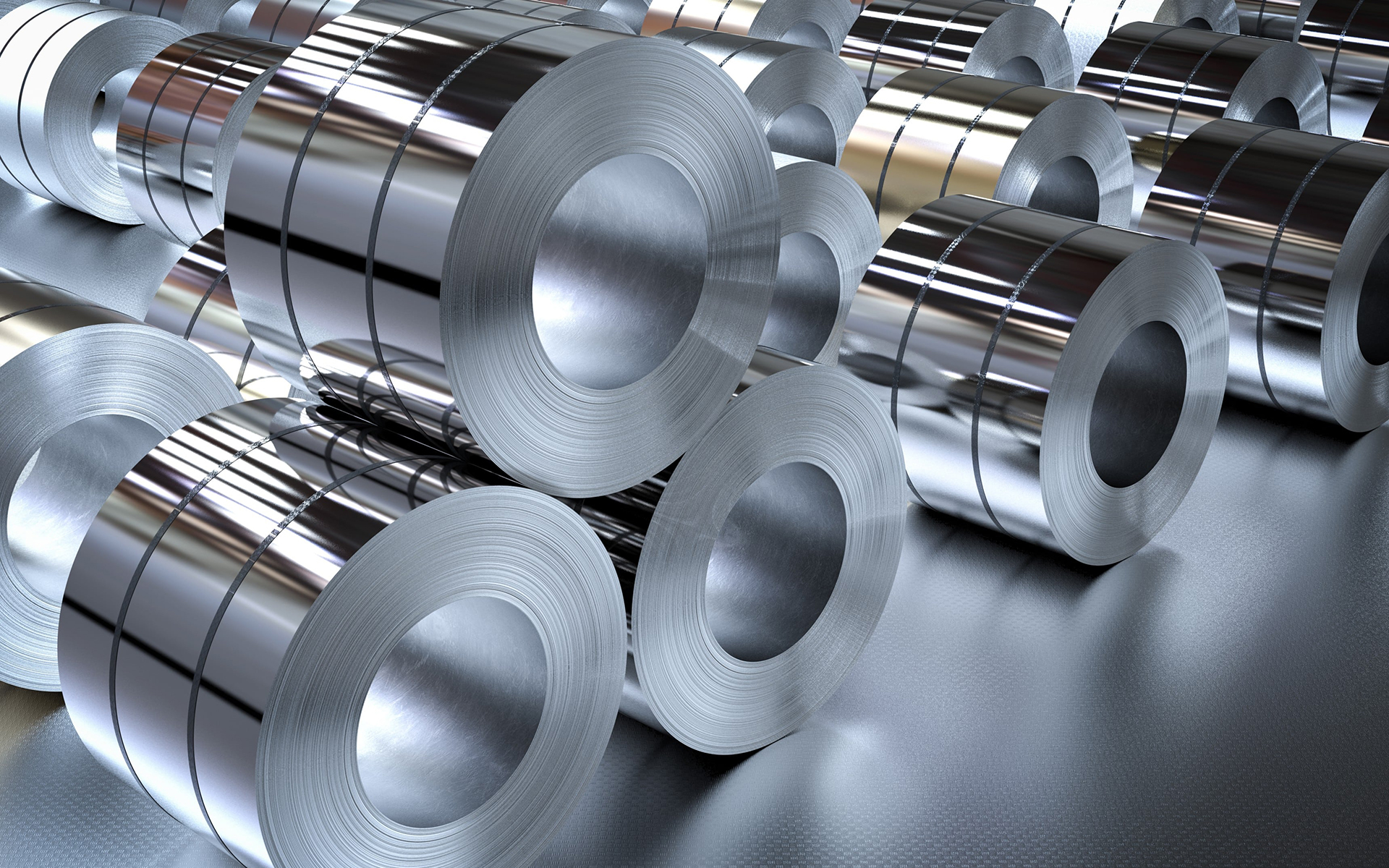

As China Brushed Process Steel Manufacturers and Custom Brushed Process Steel Suppliers, Ningbo SunRise Refined Metal Wire Material Co., Ltd. offer Wholesale Brushed Process Steel.

The company specializes in metal wire restructuring, machining, and finished metal wire selling. We not only brought in 10 sets of spheroidizing annealing furnaces, dozens of metal wiredrawing equipments and twoworld's leading automatic phosphating pickling lines, but also engaged senior engineers as consultants fromTaiwan. The raw material that we use are supplied by the well known suppliers such as Bao Steel Co., Ltd and Xingtai lron & Steel Corp., Ltd. Also, the domestic lron & Steel manufacturers can be nominated by our customers.

The materials used are alloy steel, ball bearing steel, free-cutting steel, high-quality carbon structural steel, low-alloy high-strength structural steel, etc. The annual output is 360,000 tons. It is one of the largest finished wire production bases in Ningbo. We serve all kinds of fasteners, special-shaped parts, automotive fasteners, wind power, petroleum and other fields. Ningbo SunRise is able to meet the high quality requirements of our customers throughout the whole operation process from raw materials to finished products.

English

English 简体中文

简体中文